Introduction

Concrete Strength testing is always a requirement in the field of concrete construction. Usually, when concrete batch arrives, two or three cylinders or cubes are cast so that quality control is maintained.

Question arises however when you need to find the concrete strength of already built structures than what are the options? Of course, you can cut core and test that in lab but this method involve destruction of concrete. This article is written on nondestructive tests which are used to get idea about current concrete state without destruction Nondestructive tests provide a reproducible measure of the quality of concrete in a structure without destruction to concrete

Non Destructive Tests On Concrete

Nondestructive tests provide a reproducible measure of the quality of concrete in a structure without destruction to concrete. Many such tests have been proposed, but they all still lead to difficulties in interpretation of the results.

A highly reliable in situ test to monitor concrete quality remains an elusive goal but for time being they can be used only as a quality control measure

• These tests can help determine the time for form removal

• These tests can help in the assessment of the soundness of the concrete in existing structures (e.g., after a structure has been damaged by fire)

These tests do not measure concrete strength; rather, they attempt to provide an estimate of the concrete strength through correlation with some other property. There are many non-destructive techniques but only three are discussed here which are most common.

1) Schmidt rebound hammer

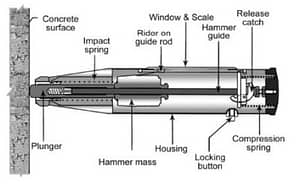

The most common non destructive test is the rebound test, using a Schmidt rebound hammer.

The test measures the rebound of a hardened steel hammer impacted on the concrete by a spring (ASTM C 805).

In this method, a grid is made for results uniformity as shown in the picture below and average readings are calibrated using graphs.

Empirical correlations between rebound hardness and strength can be obtained. However results are impacted by:

• Surface finish of the concrete being tested

• Moisture content of the concrete

• Temperature

• Rigidity of the member

• Carbonation

• Direction of impact

2) Penetration Resistance Test

This type of test involves measurement of the resistance of concrete to penetration by a steel probe (Windsor probe) driven by a given amount of energy, as described in ASTM C 803.

It consists of a powder-activated driving unit that “fires” a probe into the concrete; the depth of penetration (or operationally, the exposed probe length) is measured, and this can be correlated with strength.

3) Ultrasonic Pulse Velocity Test

The pulse velocity, V, of compressional waves in a concrete body may be related to the elastic properties by the expression (ASTM C 597)

Mechanical impulses applied to a material generate three types of waves:

• Longitudinal (compressional)

• Shear (transverse)

• Surface (Rayleigh)

The longitudinal waves are the fastest, and they are the ones that are most useful for testing purposes. The pulse velocity is affected by a number of factors:

• Contact surface smoothness

• Path length

• Temperature

• Moisture content

• Reinforcing steel

• Concrete strength

In this method sample is put between nodes (before application of gel so that there is no waves loss). Reading is noted and strenght is corelated using given equations (usually given with machine manufacturer)