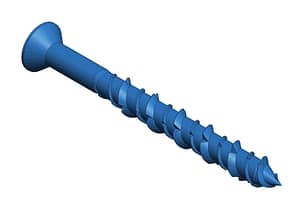

Many of us face problems when it comes how to fasten concrete screws in concrete,well with good technique and tools it is very easy.Most of time we need to fasten them to concrete or wood so the type of concrete screws that will be used depends on the type of surface we have to fasten concrete screws.Based on the type of surface we have classified concrete screws in three types.

- Light work Concrete Screws

- Medium work

- Heavy work

Light Concrete Screws

This usually comes with plastic anchors and are inserted where the things to hang are light in weight.Weight varies from 10 kg to 20 kg.You can use them in bathrooms for towel bars,showers,hangers etc.In order to fasten Light concrete screws we have to first mark holes on the surface then using hammer drill we have drill holes of appropriate length then insert plastic anchors and finally mount the anchor bracket with screws.Screw with plastic anchors are best used when we have to drill holes through concrete bricks or tile.

Step By Step Proper Guide To Drill Plastic Anchors Concrete Screw In Concrete

- First mark the holes where screws have to be inserted

- Measure the length of screw and mark it on hammer drill

- Drill the pilot hole with hammer drill

- Insert plastic anchor in the hole if the hole is large use large anchor to fit in

- Then drive easily the screw

Keep in my mind concrete must be strong otherwise it will make your plastic anchor free and turn while you are turning screw.

Medium work Concrete screws

As we discussed earlier Concrete screws is the quickest technique for joining furring strips, windows and entryways, conductor braces and electrical boxes. Drill the exceptional size pilot gap (see bundle for careful bit size) and drive the solid screw’s super-hard, huge profile strings into the solid with a force screwdriver. Purchase 3/16-in. dia. screws for lighter-work and 1/4-in. dia. screws for heavier work. The excellence of this latch is that if the piece should be eliminated, you can simply back the screw out. They’re accessible in hex or Phillips drive heads.

What are medium work concrete screws best uses?

- Furring strips

- windows

- electrical boxes

- conductor braces

- electrical boards

How to use medium work concrete screws?

Apply a unique piece in your sledge drill to penetrate a pilot gap through the workpiece (if it’s wood) and directly into the concrete to be drilled. Drive the screw with a force screwdriver. Hex heads are simpler to drive however the heads will distend marginally over the surface in the wake of fixing.

Medium work concrete screws drawbacks

- It cannot be used for weaker or loose concrete

- It cannot be used for Mortar (mix of sand,cement and water)

- We have to keep some extra screws because they break often

Heavy Work Concrete Screws

Mainly sleeve anchors come under this duty mostly drilled where the member is under heavy weight such as deck ledger boards or some heavy musical instruement.Sleeve anchors are 3/8-in. to 1/2-in. diameter and are perfect for anchoring any heavy member.

How To Use Heavy Work Concrete Screws?

First we have to drill a hole same as the size of screw and then by using hammer we have to put screw into the hole and then tighten the nut with a wrench.

Why We Should Not Use Heavy Work Concrete Screws?

Because once you put them in you cannot get them out.

Trouble We Face During Driving A Concrete Screw

In case you’re experiencing difficulty driving the screw as far as possible, first ensure the gap is sufficiently deep. In the event that it is you’re actually experiencing difficulty, there’s likely a lot of coarseness in the opening. Eliminate the screw and wipe out the gap by running the screw in and out a couple of times. Now try driving the screw once more. On the off chance if it’s again difficult, back it out and redrive it a couple of times. As a last resort, introduce another screw a couple of inches away. At long last, think about a little shorter screw for the remainder of the gaps.

Now and again you’ll have the opposite issue. The screw will turn without holding. In the event that this occurs, the material you’re affixing to is most likely excessively delicate or brittle. Attempt a more extended screw, or in case you’re utilizing a 3/16-in. screw, attempt a 1/4-in. width. You may need to utilize a concrete anchor that grows as you fix the fastener.